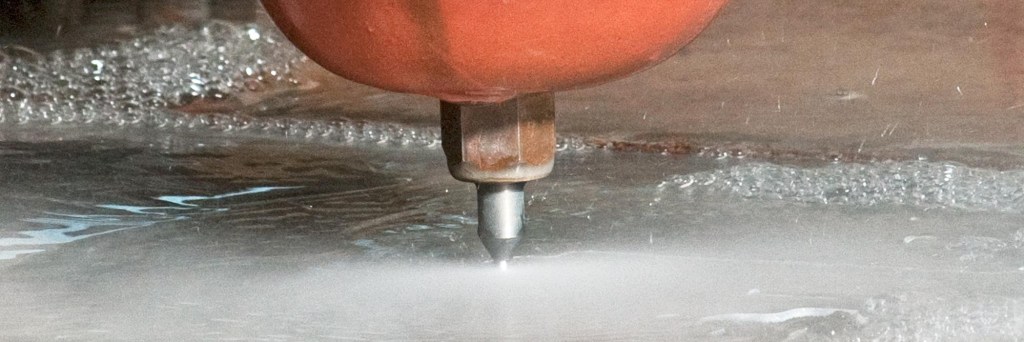

Water Jet

Next Innovations utilizes the latest technologies producing custom products of the highest quality and precision with our water jet and laser cutting technology. Using computer-aided design (CAD), computer-aided manufacturing (CAM) and computer numerical control (CNC) software, we can work directly off your custom CAD files.

Capabilities include (but are not limited to):

- Cutting area up to 72″ x 144″

- Aluminum – (2″ thick)

- Brass – (1″ thick)

- Mild Steel – (1″ thick)

- Copper – (1″ thick)

- Stainless Steel – (1″ thick)

- Stone/Tile/Concrete – (4″ thick)

- Bronze Copper Alloy – (1″ thick)

- Chromoly (CRMO), High Carbon, Tool Steel – (.025″ thick)

- Diamond Tread plate, mesh, etc.

- Various exotic metals or materials

If you need something that is not listed here, please contact us and we can process a sample for you!

Advantages:

- Cost effective means of production over a broad spectrum of quantities

- Flexibility of prototyping long and short runs

- Tolerance capabilities dependent of material thickness

- Waste reduction due to efficient nesting and programming

- Fast turnaround time